Materials and Innovation

Introduction

At GANNI, we’re on a mission to become the most responsible version of ourselves. We've set a bold, moonshot goal: to cut our total carbon footprint by 50% by 2027 (from a 2021 baseline). With nearly 70% of our total emissions coming from the fibres, fabrics and materials we use, we’re committed to making better choices every day to reduce emissions without compromising on design or quality.

At GANNI, this takes two forms: Preferred Materials and Fabrics of the Future.

Preferred Materials

Preferred Materials are those that challenge conventional practices, think organic and recycled materials. They’re well studied, readily available alternatives to conventional practises. For this, we are on a mission to ensure that 90% of the materials GANNI uses are ‘preferred’ by 2025.

To keep ourselves accountable, we developed the GANNI Fabric Score, reviewed annually, which categorises materials into: 1). Preferred 2.) Better 3). Avoid.

Fabrics of the Future

Launched in 2019, Fabrics of the Future is GANNI’s innovation lab for materials. It’s our way of championing radical new technologies that rethink the way materials are made. While Preferred Materials help us refine the status quo, for example, by switching from conventional to organic cotton, Fabrics of the Future asks a different question: What comes next? Can we grow cotton in a lab? Can we turn waste into yarn? Can we make fashion without leaving a footprint?

We partner with innovators to test and scale next-gen solutions with the goal of 10% of all GANNI’s material usage coming from Fabrics of the Future by 2025.

Preferred Materials

90% of all materials used are category 1 ‘Preferred’ and 10% of all materials used are category 2 ‘Better’, as per the GANNI Fabric Score by 2025

In 2024, 84% of all materials we used were classified as ‘Preferred’ according to our Fabric Score. This includes innovative fibres that we label as ‘Fabrics of the Future’, even though they come with their own dedicated goal (more on that later). We’re proud to report meaningful progress here, up from 74% in 2023. Making better material choices and scaling next-gen fibres remain key priorities for us, and we’re committed to staying the course.

Material Targets and Current Progress

Materials At GANNI

Overview

Chart key

Plant Fibres: 50%

Synthetic Fibres: 29%

Animal Fibres: 14%

Man Made Cellulosic Fibres (MMCF) : 4%

Fabrics of the Future: 3%

MATERIALS AT GANNI

Chart key

Cotton: 50%

Polyester: 20%

Leather & Leather Alternatives: 8%

Wool & Animal Hair: 8%

Man Made Cellulosic Fibres (MMCF) : 4%

Polyurethane: 4%

Nylon: 2%

Polyamide: 2%

Other: 1%

Cotton

In 2024, cotton made up 50% of our total material mix, a notable increase from 35% in 2023. That’s not a huge surprise to us, since many of our GANNI Icons are made from cotton staples like poplin blouses, dresses, and skirts. It only makes it more important to make sure those styles are made with ‘Preferred’ cotton (as of now, 98% of our cotton use falls into that category). We’re especially proud to see an increase in recycled cotton this year, and we’ll stay focused on phasing out conventional cotton altogether, while also exploring innovative alternatives through our Fabrics of the Future initiative.

Conventional Cotton 2%

Organic Cotton (GOTS, OCS) 86%

Recycled Cotton (GRS, RCS) 11%

Organic Cotton 96.2%

Recycled Cotton 2.4%

Conventional Cotton 1.4%

Organic Cotton 98.3%

Recycled Cotton 0.2%

Conventional Cotton 1.5%

Organic Cotton 82%

Recycled Cotton 6%

Conventional Cotton 12%

MMCF (Manmade Cellulosic Fibers)

Manmade cellulosic fibres (MMCF), like viscose, lyocell, modal, cupro, and acetate, made up 4% of our total material mix in 2024, staying fairly consistent year over year. What has shifted, though, is our uptake of certified and branded fibres, which is a solid step in the right direction. Even more exciting? We scaled up the use of Fabrics of the Future in this category, up by 13% compared to last year! That’s largely thanks to CIRCULOSE®, a next-gen fibre made by recovering cellulose from cotton-rich textile waste, like worn-out jeans or production scraps. We’re staying on this path and working to move away from conventional MMCF fibres altogether.

Certified MMCF (Rayon FSC, Viscose FSC, Acetate Naia™, Viscose RCS, LENZING™ ECOVERO™, TENCEL™ Lyocell) 78%

Conventional MMCF 7%

Fabrics of the Future 15%

Certified MMCF (Rayon FSC, Viscose FSC, Acetate Naia™, Viscose RCS, LENZING™ ECOVERO™, TENCEL™ Lyocell) 67.90%

Conventional MMCF (Viscose, Rayon, Lyocell, Modal, Rayon, Acetate) 30.20%

FOTF (Viscose made with Circulose®) 1.90%

LENZING™ ECOVERO™ Viscose, TENCEL™ Lyocell, REFIBRA™, FSC Certified, Infinna 55%

Conventional Viscose 45%

LENZING™ ECOVERO™ Viscose 27%

Conventional Viscose 73%

Polyester

In 2024, polyester made up 20% of our material mix, which is a reduction of 4% from last year. We’re happy to report an increase in our use of Fabrics of the Future here, specifically cycora® and Tex2Tex™ (both fibre-to-fibre recycled polyester). It might not be a huge share yet, but this space is still developing.

Conventional Polyester (Standard + Metallic) 23%

Recycled Polyester (GRS, RCS) 76%

Fabrics of the Future 1%

Recycled polyester 82,5%

Conventional (virgin) polyester 17%

Fabrics of the Future (Cycora) 0,001%

Recycled polyester 96%

Conventional (virgin) Polyester 4%

Recycled polyester 82%

Conventional (virgin) Polyester 12%

Wool & Animal Hair

In 2024, wool and animal hair made up 8% of our material mix. Even though it’s a smaller share, prioritising preferred fibres is key here, as wool and animal hair can be pretty carbon-intensive. We’re pleased to see an increase in our use of responsibly sourced wool and other animal fibres like mohair, alpaca, and cashmere, alongside a steady use of recycled wool. Our priority with recycled wool is to scale its use without compromising the quality of our products. The challenge here is that recycled wool doesn’t give our garments the beloved softness we crave, especially in our knitwear, so it often needs to be blended with other fibres. We’ll continue exploring its potential, reducing the use of conventional wool and focus on finding next-gen materials for this category.

Responsibly Sourced Wool (RWS, RAS, RMS, GCS) 41%

Recycled Wool (GRS) 38%

Conventional Wool 21%

Alpaca (RAS), Merino (RWS), Mohair (RMS) 16%

Organic Wool 8%

Recycled Wool 44%

Conventional (virgin) Wool 32%

Recycled Wool 54%

Conventional (virgin) Wool 39%

RWS Merino 7%

Responsibly Sourced Wool (RWS, RAS, RMS, GCS) 41%

Recycled Wool (GRS) 38%

Conventional Wool 21%

Leather & Leather Alternatives

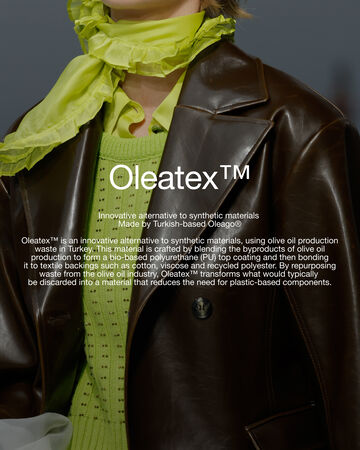

No virgin leather here! After a successful phase-out of virgin leather from all of our products at the end of 2023, we’ve just completed our first full year without any use of virgin leather in our collections, getting us closer to our carbon reduction goal. To achieve this goal, we’ve worked hard to switch some of our iconic pieces to recycled leather or produce them with next-materials from our Fabrics of the Future initiative! Namely, we’ve successfully scaled our use of Oleatex™, and Pelinova®, which was a big milestone. We will continue this important work, advancing the use of innovative materials instead of leather, and working on exploring the potential of recycled leather, so we can decrease the use of synthetics in products typically made with leather.

Recycled Leather 76%

Fabrics of the Future 24%

Conventional (virgin) Leather 71.8%

Recycled leather 23.8%

Fabrics of the Future (Mylo, Ohoskin, Oleatex, Vegea) 4.4%

Conventional virgin Leather 80%

Recycled Leather 12%

Vegea ™ 8%

In the Spotlight

The Impact of phasing out Leather

We set our goal to phase out virgin leather back in 2019. Looking at our carbon footprint at the time, we realised that leather was responsible for the majority of our material-related emissions, even though it only made up 9% of our material mix. From there, it was clear we wouldn’t be able to lower our emissions while still using virgin leather. Discover the full story in last year’s Responsibility Report. We phased out virgin leather in ready-to-wear by 2021, and in footwear and accessories by the end of 2023.

Did it make a difference? Absolutely. From 130,000 kg of virgin leather used in 2021 to 40,000 kg in 2023, and finally zero in 2024, phasing out virgin leather has resulted in significant emissions savings. As we mentioned, emissions from our products (also known as "purchased goods") make up more than 70% of our total carbon footprint. That means progress here has a big impact overall. Since a large chunk of those emissions comes from the raw materials we use, removing virgin leather and replacing it with lower-impact alternatives was bound to show up in our numbers. Our product emissions dropped from 31,650 tCO2e in 2021 to 22,750 tCO2e in 2024, marking a 28% reduction from the baseline in this category. We’re also seeing a clear positive impact when we look at our average carbon footprint per product, which has gone down by 13% since 2021.

Reduction in Scope 3, Category 01: Purchased Goods

2021

31,650 tCO2e

2024

22,730 tCO2e

TOTAL REDUCTION

28%

Lots of big numbers, so let’s break it down. What does replacing virgin leather actually mean for a product’s carbon footprint? Below are three fictional scenarios of LCAs (life cycle assessments) of the Cleated Mid Chelsea Boot, one made with virgin leather, one with recycled leather, and one with Oleatex™, a next-gen material from our Fabrics of the Future initiative.

We’re proud of the progress we’ve made through our materials strategy, and we’ll keep pushing to rethink our material choices in order to keep cutting our carbon footprint. But to continue on our decarbonisation path, simply choosing preferred materials won’t be enough. Even with virgin leather out of the picture, other high-impact materials are still in the mix, wool being one of them. Virgin wool carries a hefty carbon footprint (even when certified), and our volumes are expected to grow over the coming years. We also need more scalable leather alternatives that we can use alongside recycled leather. This is where our Fabrics of the Future programme comes in.

.jpg?sw=360)

Fabrics Of The Future

Fabrics of the Future looks featured in SS25—The Craft Fashion Show

GANNI’s Fabrics of the Future programme was set up in 2019 by GANNI to research, test and eventually scale innovative materials that challenge conventional material methods, paving the way for the future of fashion.

Our end goal is that 10% of the materials we use is coming from Fabrics of the Future, because this will have the largest impact on reducing our carbon emissions. The goal also sets us apart from only launching small capsule collections and piloting innovations, to scaling them at a commercial level, so innovative fabrics essentially become accessible to GANNI’s community. 2024 has been a remarkable year for GANNI and Fabrics of The Future: we advanced towards our target goal and we showcased an increasing number of new materials, both in the collection and on the runway.

Fabrics of the Future Results

10% of category 1 ‘ Preferred’ materials are from Fabrics of the Future by 2025

We are pleased to report that in 2024 Fabrics of the Future represented 3% of our materials used. Although it did not fully reach the objective we had initially set for last year (5%), it's a great start and gives us the motivation to keep going.

We used Fabrics of the Future alternatives for some of our highest carbon emitting materials, being leather, cotton and polyester based on 2021 baseline data, which drove our leather phase out and material strategy. Specifically, leather alternatives made up 68% of total Fabrics of the Future material mix, followed by polyester alternatives with 24% and viscose with 8%.

Fabrics of the Future innovators that we launched with in 2024 as alternatives to viscose, leather and polyester were, CIRCULOSE®, Oleatex™, PELINOVA®, cycora® and Tex2Tex™. We increased the number of commercial Fabrics of the Future from 1 to 5 from 2023.

Furthermore, in 2024, we significantly increased the number of styles designed for production, referring to individual product designs, not the total number of items produced.

In 2022, we created 9 styles using Fabrics of the Future (FOTF). In 2023, that number rose to 17, and by 2024, it had jumped to 88. These numbers refer to products developed and committed to production in that calendar year, meaning not all were available for purchase in 2024.

This growth shows how FOTF is being embraced across the entire company, and highlights GANNI’s commitment to integrating these innovative materials from design through to development and production, all the way to the customer.

Number of Fabrics of the Future Styles Designed for production

2024

88 Styles

2023

17 Styles

2022

9 Styles

Fabrics of the Future integration into our collections does not come without challenges, specifically related to quality standards, premium prices, availability and supply chain implementation. In the current volatile fashion industry environment, it is normal to see next-gen innovators struggle to scale their business and achieve widespread adoption. Therefore, we need to work, test and collaborate with them for longer time periods, to ensure we reach commercial feasibility and viability, without compromising at all on quality and durability. Currently, we have more than 70 innovative materials in our portfolio, across different material areas. At GANNI, we classify the innovators in four different phases based on their maturity stage and collaboration mode with our teams.

In Exploration

Materials that we find exciting and are currently exploring.

Promising

Materials with clear potential that we're evaluating for GANNI products. We're prototyping and developing these to bring the material closer to a possible launch.

Viable

Materials we’ve either showcased on the runway but aren’t ready for commercial launch, or materials previously used in collections but not consistently.This stage is very critical for the commercialization of Fabrics of The Future, since it is the moment to tackle and overcome the main barriers to scale.

Graduates

Materials that have successfully launched and are now regularly used across collections. We know how to work with these materials, and we’re excited to feature them season after season.

Considering that as of now, only 5 are “Graduates” Fabrics of The Future, we are aware that the journey is long but we strongly believe in the Fabrics of the Future as a necessary component to making the fashion industry more responsible.

Since the very beginning, we have always believed in the potential of Fabrics of the Future. We are extremely proud of the 3% result we have achieved in 2024, since it shows how innovation is possible and achievable even in the fashion industry. At the same time, we know the work is not done yet and 2025 is a crucial year for GANNI in this area. To reach our ambitious objective of 10% by the end of this year, we will focus on scaling our “Graduates” Fabrics of the Future, while exploring new innovations that hit our standard of sustainability and high quality. It is important to underline that without scaling and expanding the use of Fabrics of the Future will not be possible to reach our 50% carbon reduction goal by 2027, since materials represent the biggest source of our emissions.

We are aware that we might not achieve the full objective by the set deadline. Integrating these innovations in our business could become increasingly harder in the next few years due to the status of the industry and the natural challenges of these materials, such as early stage phase, lack of infrastructure and slow adoption. Nevertheless, such a goal is helping the GANNI teams to stay focused and to keep raising the bar in innovation.